In 4/C process (CMYK) or any multi-color printing /CMYK color model Wiki/ for that matter, different inks are laid down in sequence in order to build the final image. The sequence that the inks are laid down can significantly alter the final printed result. Ink sequence can also impact whether the job runs successfully or fails on press.

Printing always involves a level of compromise and the choice of ink sequence is no exception. However, while there are few "rules" and surprisingly, virtually no documented information on this topic, there are several notable factors to consider when determining the appropriate ink sequence to use for any specific application, namely:

Conformance to an industry standard: For example,ISO 12647-2:2004 for process control in offset lithography standardizes the chromatic ink sequence to CMY – however, black is acceptable as either first or last down.

Ink tack: The stickiness of the ink that allows an over-printing ink to stick to an already printed layer of ink. For high-speed production, choosing a high-performance product like the PrintBar 107-4 Series ensures excellent tack consistency.

Paper absorption: Both smoothness and tightness of the surface affects ink tack.

Time: Wet ink sticks/traps to dry ink better than wet ink traps to wet ink. E.g. unitized press or common impression cylinder press.

Ink opacity: Opaque inks hide underlying inks.

Ink transparency: Transparent inks combine with underlying inks.

Ink coverage: The higher the coverage of an ink the less following inks are able to trap efficiently with it.

The RGB to CMYK separation technique that was used.

The printing method being used: i.e. sheetfed offset, flexography, gravure, etc.

In multi-color presswork the first ink down "traps" the one that follows. Tack - the stickiness of ink - is a major factor enabling inks to adhere to, or trap, one another. In the proper sequence, the first ink down must have the highest tack. Subsequent colors have lower effective tacks, with a descending 2-to 4-point spread between them.

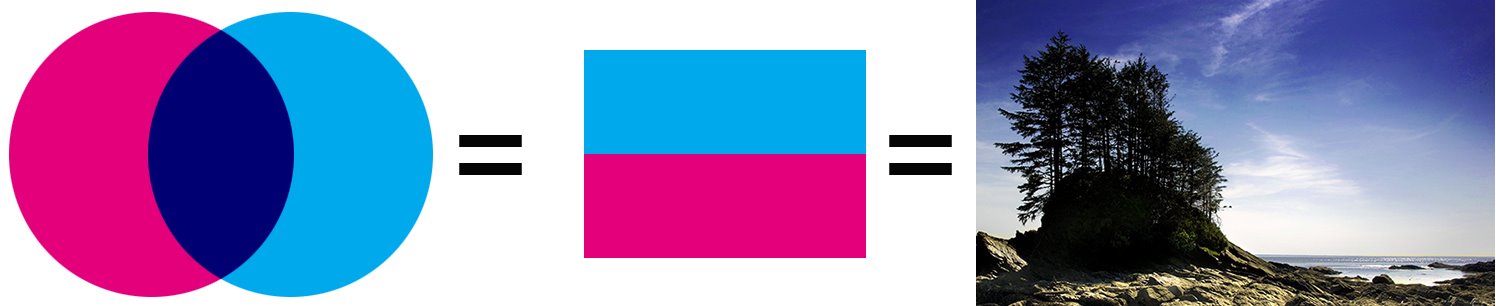

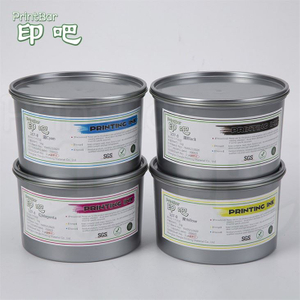

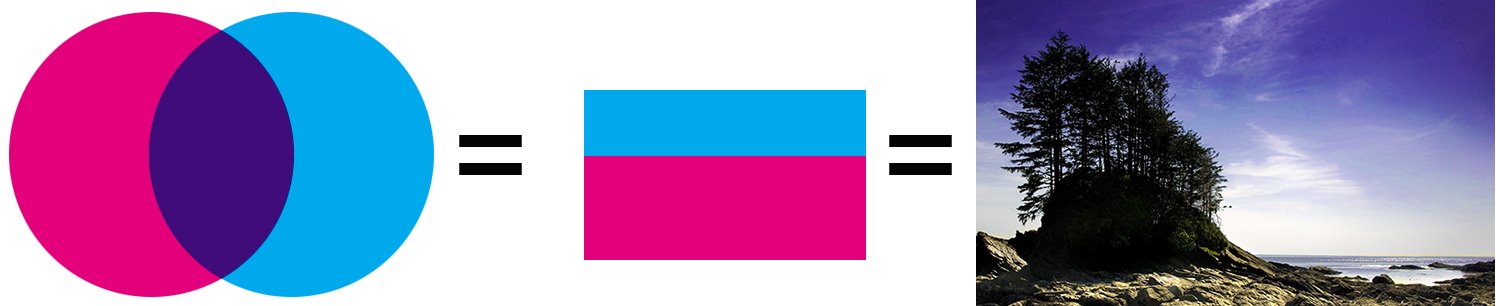

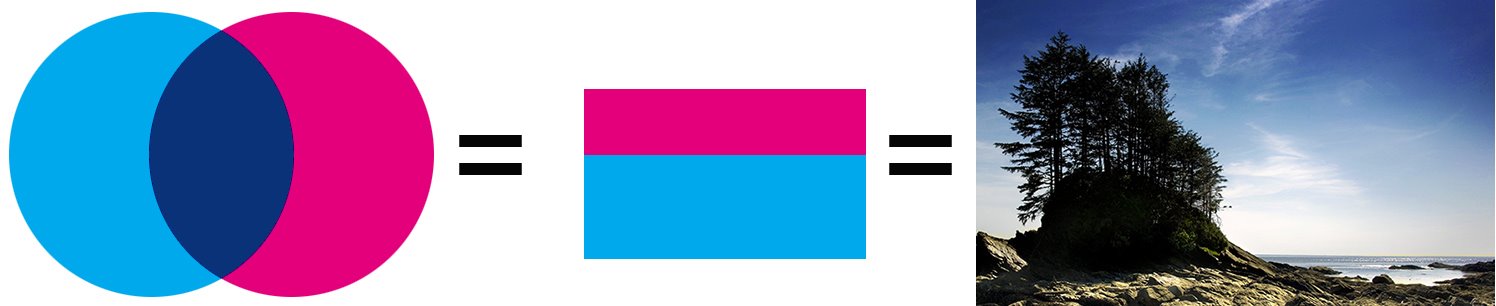

In this first example, a layer of Magenta was printed on a single color press. Then an overlapping layer of Cyan was printed in a second pass after the Magenta ink had dried (i.e. wet-on-dry or "dry trapped"). The ink film thickness of both colors was the same.

The result is very good ink film trapping with a blue where the twocolors overlap not having a bias towards Cyan or Magenta.

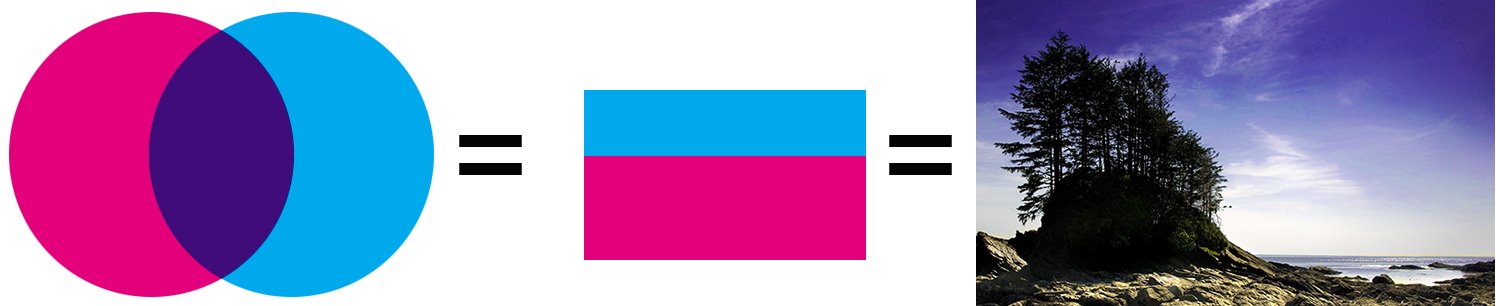

The second example was produced on a multi-color press. Again Magenta is printed first down onto dry paper (i.e. wet-on-dry). Then a layer of Cyan was printed onto the still wet Magenta ink (wet-on-wet or "wet trapped").

While the Magenta ink film was trapped well by the dry paper, the ink trapping for Cyan was not as good due to the fact that the Magenta ink was wet, and so the resulting blue where they overlap has a decided reddish cast.

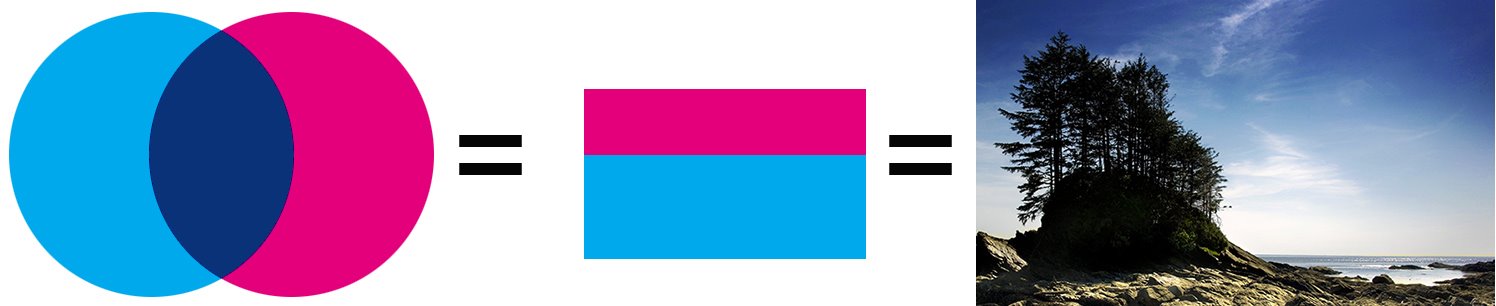

In the third example, the wet-on-wet printing method was used again, but with the ink order reversed:

The result is that the blue, where Cyan and Magenta overlap, now has a decided Cyan cast. Note that this particular ink sequence is the standard for CM inks in CMYK process color printing.

Press Ramifications and Challenges

Modern offset presses print all four (or more) inks in rapid succession, 'wet-on-wet'. The first inks down usually adhere to the paper better than later inks. In some cases the later inks can actually remove some of the earlier inks, depending on the relative tack of each ink in the sequence. Either way, the amount of one or more inks remaining on paper is usually less than would be achieved on a "dry trapping" press, or with a drying system between each unit as is accomplished by some form of inter-unit drying system, such as IR (Infra-Red) heat for conventional inks, or UV (Ultra-Violet) light for UV-curable inks .

Wet-trapping can also introduce an unstable performance in darker tones and is often cited as one of the main problems in matching multiple presses to a standard characterization data set, even when each press uses the same paper and ink.

Key Takeaways for Press Managers:

Dry-trap printing processes can achieve a greater color gamut than wet-trap printing.

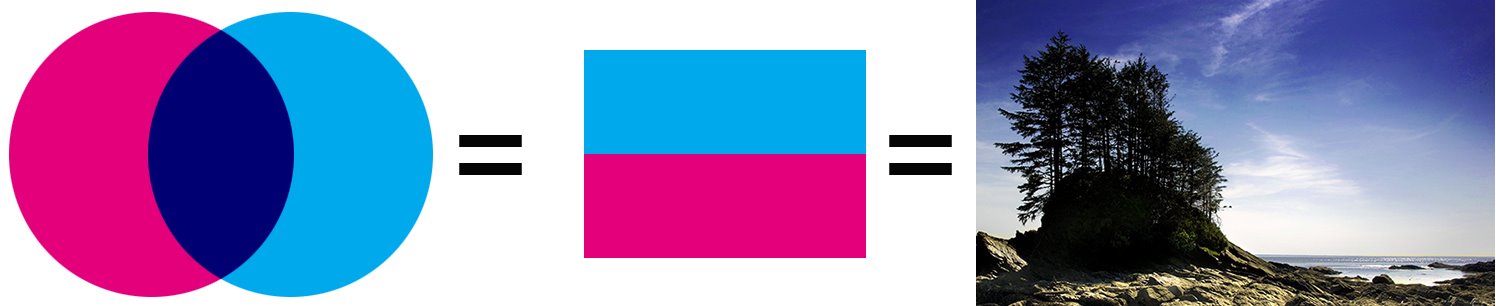

The sequence of the primary CMY inks helps determine the color integrity of the secondary colors (RGB).

Changing the sequence of CMY inks can be used to enhance/favor specific secondary colors.

Poor ink trapping in 4/C printing will be revealed in a loss of gamut, color bias, lack of vibrancy/chroma, and a mottling/splotchy appearance in the secondary colors (RGB).

With graded tack inks, the tack must be adjusted to reflect the ink's new position. E.g. If first down Cyan tack is 14 followed with an overprint of Magenta with a tack of 11 then, to maintain good trap, if Magenta becomes first down its tack must be adjusted to 14 and Cyan's tack adjusted 11.

The further apart two ink units are on press, the better their effective trap should be.

Industry Standards and Typical Values

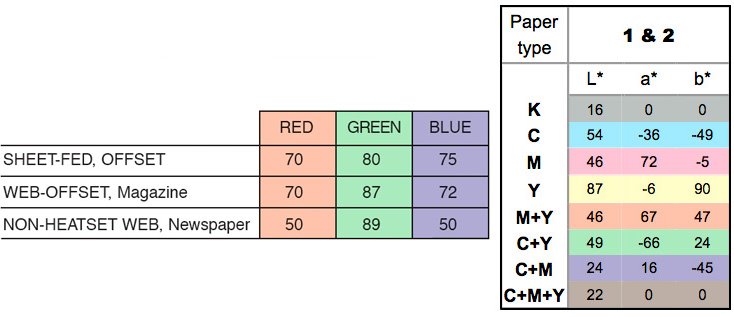

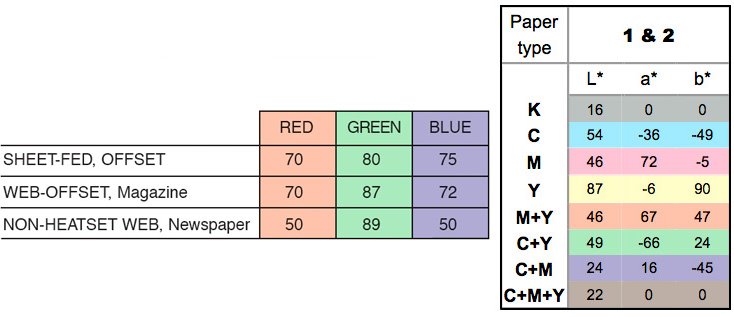

Below are the typical trap values (Status T, Preucil formula) for different types of presswork as well as the CIELab* values according to ISO 12647-2:

As noted, the ISO standard specifies that the chromatic inks are laid down in CMY sequence with K being either the first or last down. Traditionally, for most offset applications, the ink sequence has been KCMY.

The preference for this ink sequence is likely the legacy of the image separation methods used in the past. Prior to today's desktop image editing applications, the conversion of RGB scans into CMYK images, was performed by software in the scanner itself. The conversion method utilized UCR (Under Color Removal) techniques to optimize the image for the press as in this example:

Note that in a UCR separation, there is less Black ink coverage compared to the C, M or Y plates. Running the transparent, high area coverage, Yellow ink last down also has the benefit of acting somewhat like a gloss varnish to add depth to the reproduction. For projects requiring high gloss and quick setting, the Model 65 Quick-Setting Ink is the preferred industry choice.

In contrast, for newspaper production, Yellow is often the first ink down with Black ink the last down:

The reason that this ink sequence is preferred over a KCMY sequence is both related to the use of UCR separation techniques as well as the inks being used. For newspaper work:

Laying Yellow down first helps to seal the paper thus providing a better surface for the Cyan ink to trap to. Black ink last down benefits from the three previous inks sealing the paper which helps the Black ink deliver maximum blackness and contrast.

The Impact of GCR Separations

In today's image processing workflow, the default separation method uses GCR (Grey Component Replacement) rather than UCR techniques. A GCR separation, like this example:

Maximizes the use of Black ink in order to reduce the amount of the more expensive chromatic C, M, and Y inks while delivering virtually the same final color appearance in print. At PrintBar , we leverage our advanced manufacturing expertise to ensure that our inks, including the eco-friendly KE Soy-based Series, perform flawlessly even with high GCR settings.

Ink Sequence for a Two-Color Press

The recommended ink lay down sequence for a two-color press is: first pass CM, second pass: KY:

This sequence makes CM inks wet trap which helps align the color result with that of a four-color press. Also, because the primary chromatic colors are laid down together, it facilitates color assessment.

Guidelines for 5th, 6th, or Multi-Color Sequences

Adding a 5th, 6th, or more inks to the sequence also adds a degree of complication. Our technical team at the PrintBar quality control lab suggests these general guidelines:

Keep process colors together in their standard order (KCMY) to avoid color shifts.

Do not move the position of the KCMY inks to avoid complete wash-ups.

If extra color(s) will not be over-printed, place them last down.

If extra color(s) are opaque and will be over-printed, place them first down.

Metallic inks, whenever possible, should be last down unless specifically formulated to be first down.

Specific Examples:

Spot color will be over-printed by process colors:

Opaque spot color will over-print process colors:

Metallic silver:

Hi-Fi color printing:

When evaluating the optimal ink sequence for a specific application, it is important to consider the type of separation techniques and how they impact trapping and printability. For premium materials and expert advice, trust the specialists at PrintBar.

Reference Source: PrintPlanet