A2060 Water - based super high gloss varnish

1. Product introduction

Water - based super high gloss varnish,It has high glossiness, High wettability, good leveling ability, wet adhesion resistance, fast drying speed, good printing suitability, etc. Both online and offline are common.

2. Technical parameters

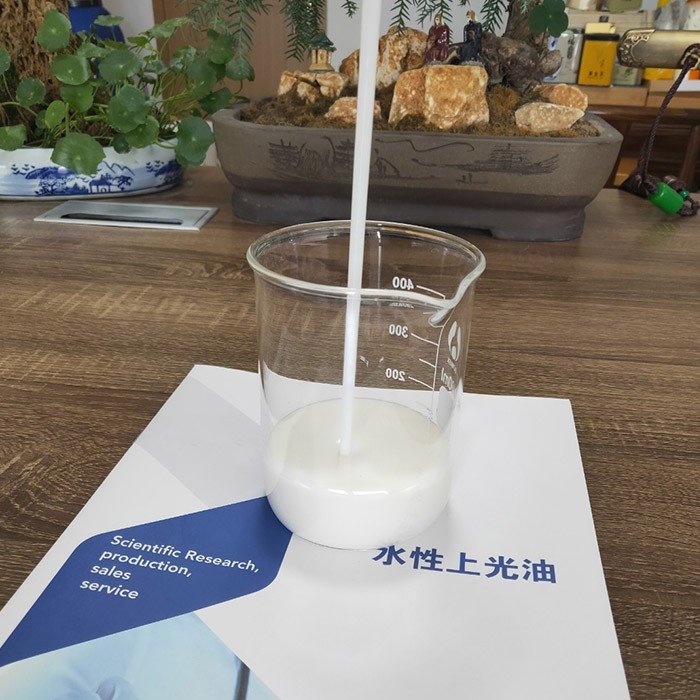

Appearance: Milky white translucent liquid

Solid content: 40±1%

Viscosity: 50±5 seconds (25℃ coating # 4 cup)

PH: 8.0±0.5

Glossiness: 85±5 (60° gloss meter)

Wear resistance: Ø300 reps (4 LBS pressure)

3. Usage and Precautions

Add proper amount of diluent (water) or alcohol and water mixture to dilute according to the use condition. In order to achieve gloss and wear resistance requirements, according to the paper, roller coated with gloss plus diluent 5 ~ 15%,On-line Varnishes using stock solution,If the varnish viscosity is too high, add an appropriate amount of diluent to adjust to the appropriate viscosity.

The amount of varnish should be in accordance with the principle of quality. If dilute it too much will affect the gloss, wear resistance and levelling property ;On the contrary, insufficient dilution will also cause the leveling of varnish is not good, drying rate is slow.

Amount of varnish depends on the quality and gloss of the paper.General online varnish: 2-5G /㎡, offline varnish: 3-7g/㎡.

Drying methods: Infrared drying, hot air or heating tube drying.Drying equipment during operation, the temperature displayed by the watch head shall not be lower than 70℃.

After coating for 12 hours, the performance of the varnish can reach the best state.

Can use water to clean equipment, dry varnish can be IPA or alcohol to remove.

This product is alkali soluble varnish,When sticking the carton (back up paper), please try to choose neutral or weak base adhesive (PH≤10),In the use of starch glue, caustic soda glue (yellow glue),Please strictly control the amount of glue to avoid excessive glue penetration gloss oil and dissolve gloss oil resulting in sticky paper.

4. Packaging And Storage

50KG/200KG plastic drum, sealed and stored in a cool place, shelf life of 6 months.