Overprint and overprint accuracy control

Accurate overprinting is a common quality requirement for printed materials.The source of the overprint error is multi-faceted, from the current three-dimensional printing of high-resolution CTP output plate application considerations, basically no longer need to consider the plate process error (even if there is an error, but also belongs to the systematic error, discretionary non-manpower can be adjusted).

Nowadays, advanced high-precision printing machines are commonly used, mostly with automatic plate loading function, so the existing plate deformation is uniform for the four plates, and no longer consider the abnormal bending deformation and tensile deformation produced by the technical difference of manual plate loading as an important factor.At the same time, due to three-dimensional printing using UV inks, more external drum CTP, so the deformation of the plate can also be ignored (due to the deviation generated by the baking plate is not considered here).

In addition, due to the use of lenticular material direct printing method, nowadays the lenticular material is mostly used PET material, there is no such as paper fibre as sensitive to humidity material, so the change of temperature and humidity on the substrate material material size change impact is not as fast as the paper obvious.

Now the three-dimensional printing, from the plate making process, plate making equipment and substrate materials with the previous film plate application of paper printing differences are obvious, and are to more stable direction of improvement; therefore, now the three-dimensional printing overprint accuracy improvement more from the printing equipment to consider the improvement of the changing factors [1].

1.Overprint errors in general printing

For multi-colour printing machine, the printing plate will be installed on the machine, each plate must have a more precise registration position, in order to get the rules correct, clear image of the printed matter.If the position of the plate is offset, the prints of the order of tone, colour should be changed, the clarity of the image will also be reduced.

Nowadays, the design and manufacturing level of the printing machine is relatively high, the overprinting accuracy can reach 0.01mm, therefore, as long as the debugging of the printing machine, it can completely guarantee the mechanical requirements for the registration accuracy of the printed matter.However, the printed matter is the use of printing plates, substrates, inks, printing machinery to cooperate with each other, mass production of products, printed matter of the overprint error is the printing process, a variety of overprint error accumulated.Therefore, understand the requirements of overprinting accuracy of printed matter, analyse the pattern of change of overprinting error, the use of appropriate measures in order to reduce the overprinting error of printed matter to a minimum.

1.1 Requirements for overprint accuracy of printed materials

The human eye in the normal observation distance, the ability to identify fine lines up to 0.1mm. printed image of the order of the general reproduction with the dot, the diameter of each dot is actually less than 0.1mm, alone the human eye is unable to identify open, therefore, people put 0.1mm as a benchmark for the consideration of overprint accuracy.

However, the human eye is extremely sensitive to changes in colour, and various colours can be identified by the human eye even if they are less than 0.1mm in overprint.Thus, in the printing process, from the point of view of the colour change, the overprint precision requirements are more stringent.

Printing with multi-color offset presses, ink overprinting more wet over wet, that is, in the first colour is completely in a wet state, the second colour is printed; even UV drying press, not all of them are inter-colour drying.In the case of a stable supply of ink, overprinting deviations will make the printed matter of the order, colour changes.Overprinting, the previous colour of the ink is always printed in the next printing unit rubber blanket in different places, and from this part of the transfer to the next print sheet.In this case, not only produces local subtle step changes, but also to occur the dot increase.This dot gain, which involves the transfer of ink, is through the indirect secondary inking occurs, even if the dot expansion value is very small, but also cause a large step and colour changes.Some experiments have shown that if the overprint error exceeds 0.02 ~ 0.03mm, the human eye will find the colour change, so in the wet over wet printing, the allowable overprint error fluctuations must be equal to or less than 0.03mm.

1.2 General printing overprint error rule of change

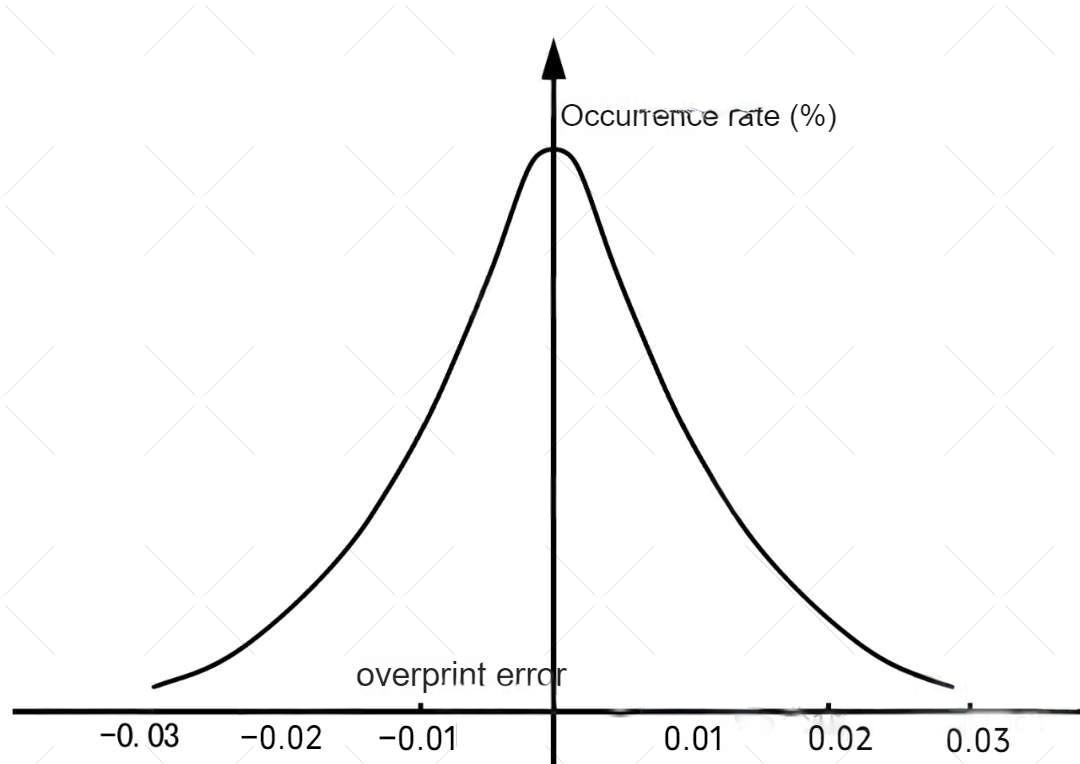

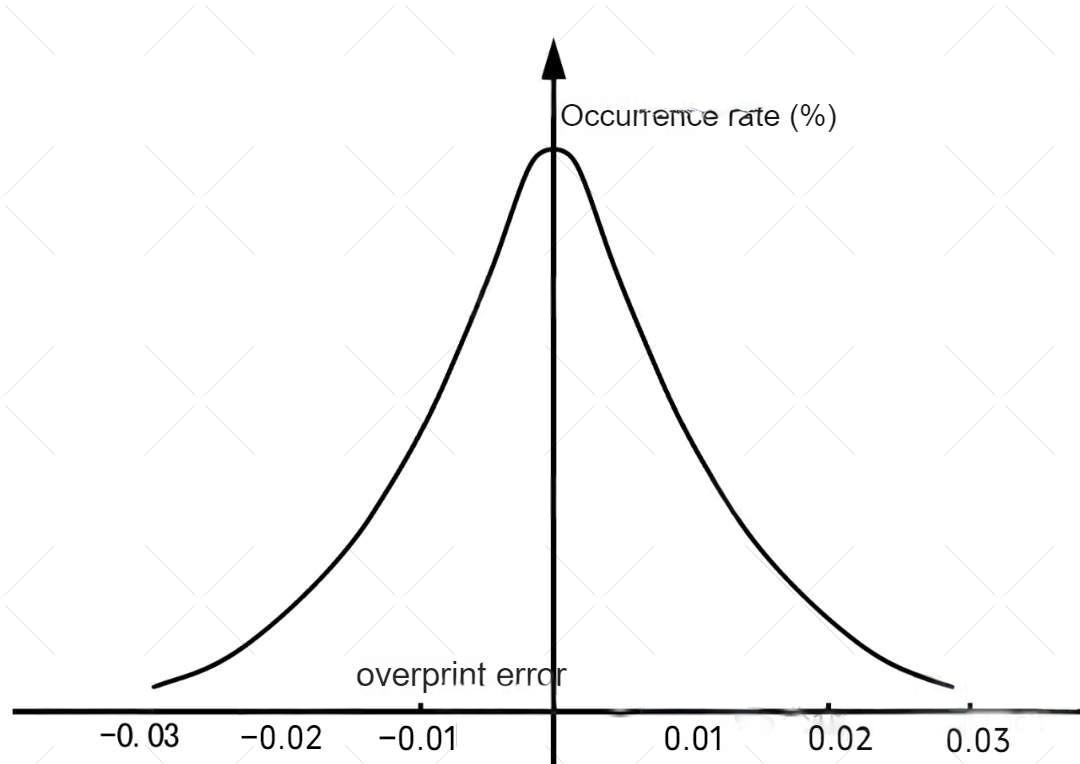

A printing plate with accurate positioning marks is mounted on the printing machine and the overprint error is measured.In a right-angled coordinate system, the overprint error is represented by the horizontal coordinate and the rate of occurrence of the error is represented by the vertical coordinate, resulting in the curve shown in Figure 1-1.The curve is very similar to the bell-shaped curve of Gauss's law of normal distribution, indicating that the overprint accuracy is characterised by a normal distribution.

(1-1)Normal distribution curve of overprint error

Overprint error of the normal distribution curve shows that the printing process, there is a large overprint error, for example, greater than ± 0.03mm of the print is very small, and 100 per cent of the register no overprint error of the print is actually not; in most of the print on the appearance of the medium overprint error.Therefore, as long as the overprint error meets the normal distribution, you can use the law of normal distribution to evaluate the overprint accuracy of the print.

It has been experimentally demonstrated that the proportions are distributed as follows, categorised by single, double and triple errors:

The actual number of errors in the ±1σ range is 68.26 per cent;

The actual number of errors in the ±2σ range is 95.45 per cent;

The actual number of errors in the ±3σ range is 99.73 per cent.

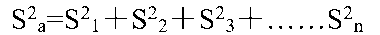

If you encounter more than two overprint error factors, each overprint error are considered to have a normal distribution, and add them together to produce a new normal distribution, this new normal distribution has a new standard error, which can be calculated in the following formula:

where Sa is the new standard error of the new normal distribution and S1, S2, ......Sn are the standard errors of the individual normal distributions.

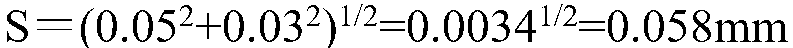

If the continuation error of a printing machine is known to be 0.03mm and the transmission error is 0.03mm, the overprint error should be:

1.3 Overprint error of the printing machine

The overprint error of the printing machine, mainly from the renewal error and paper transmission error.

People after a long period of production practice that the continuation of the paper overprint error of 0.03 ~ 0.05mm, the paper error of 0.02 ~ 0.03mm. It has also been proposed that 98 per cent of the printed sheets, when the continuation of the paper overprint error of 0.02mm, the paper overprint error of 0.01mm, can be printed out of high-quality fine mesh prints.However, to increase the precision of the printing machine by one per cent, the cost will increase a lot.Therefore, the general overprinting accuracy does not have to exceed the level required to achieve the process.Different types of printing machines to get the print overprint error is not the same.

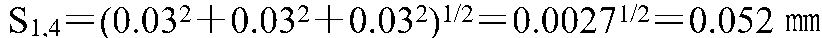

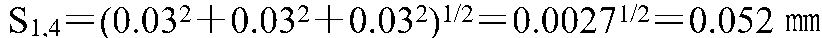

Colour printing with four-colour offset presses, only after a renewal of the paper, the image in the position of the paper after the first colour to go, the other several colours are the same.But the paper in the process of transmission between the various printing units, the sum of the overprint error occurs, it is the actual overprint error between the monochrome on the composition of the printed sheet.If the paper error value of 0.03mm, the use of normal distribution law, you can find the first colour and the fourth colour on the sheet between the actual overprint error, that is

Printing overprint error, is the printing reproduction of the various processes in the overprint error accumulation of the sum.In the actual production, in order to improve the quality of printing, often the printing speed down some, which can reduce the error caused by the paper or machine.In addition, the fine mesh of high-quality prints, often to pass the paper error of 0.02mm, renew the paper error of 0.03mm.

1.4 Positioning marks

Printing process, the cause of overprint inaccuracy of the reasons are complex, and therefore the form of performance is not the same.For example:

1, there are images between the line drawing overprinting is not allowed;

2. Overprinting between the various colours of ink is not allowed;

3. The overprinting of the field part is not allowed;

4. The overprinting of the dot or fine line part is not allowed;

5, front and reverse side due to image displacement caused by the front and reverse side of the overprint is not allowed;

6, the interval between the front and back of the printed sheets of overprinting is not allowed.

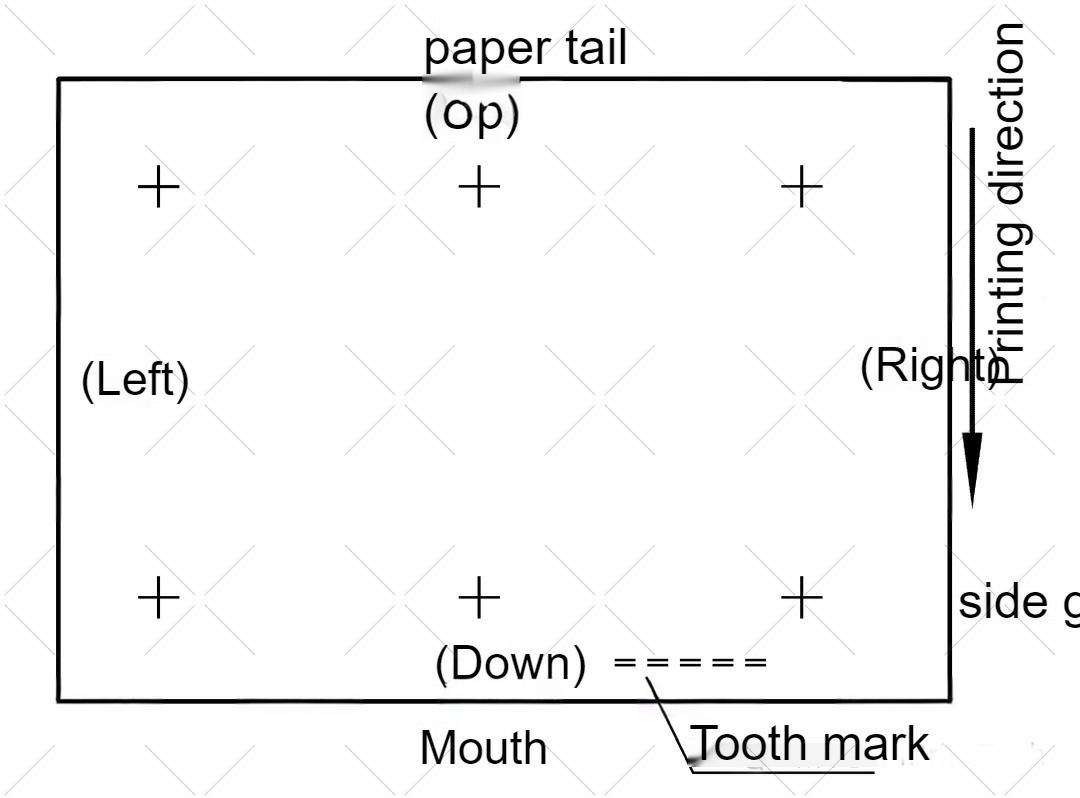

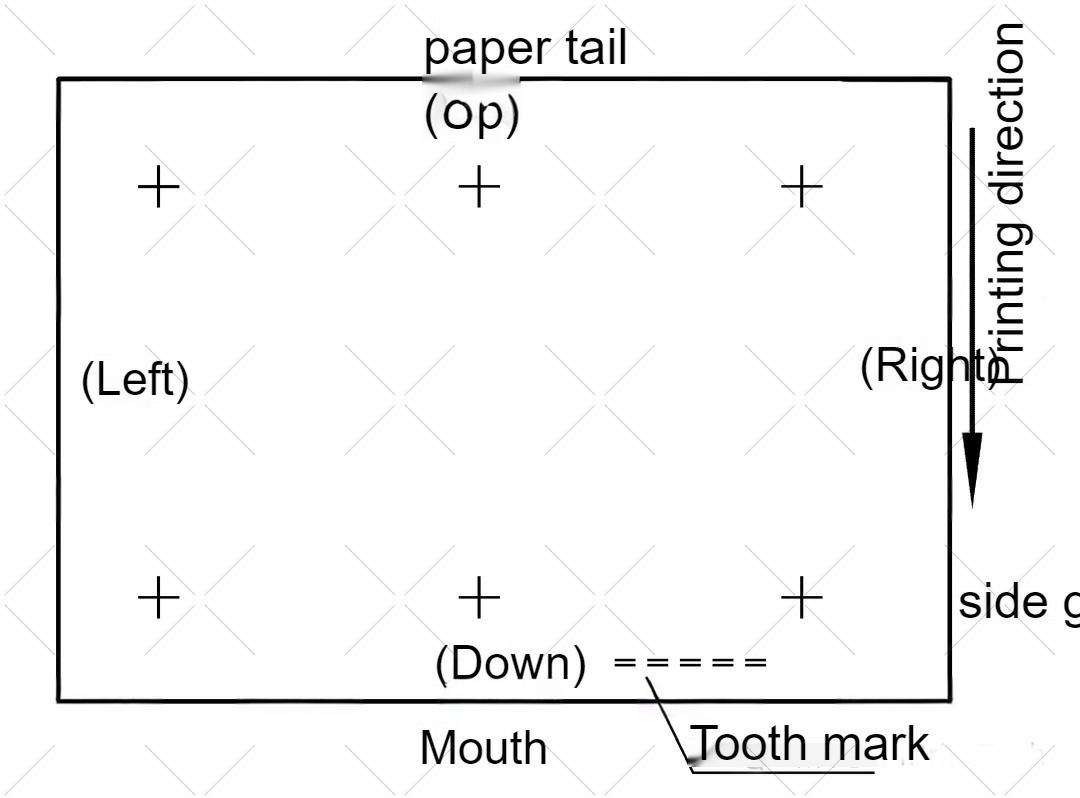

(1-2)Cross marks and names of parts of the sheet

In order to determine the degree of accuracy of overprinting, usually using the "positioning marking method" to detect changes in overprinting at any time, so that the printing operator to take timely measures to improve the accuracy of overprinting.

Offset printing process, the general use of the "crosshair marking method" positioning, this cross mark, in the platemaking on the four corners of the plate and the middle part of the mark, as shown in Figure 1-2, after printing with the edge of the paper together with the cut off.In multi-color printing, you can cross from a variety of colours to mark the degree of misalignment or skewed, check the print up and down, left and right, as well as diagonal and other directions of the overprint situation.

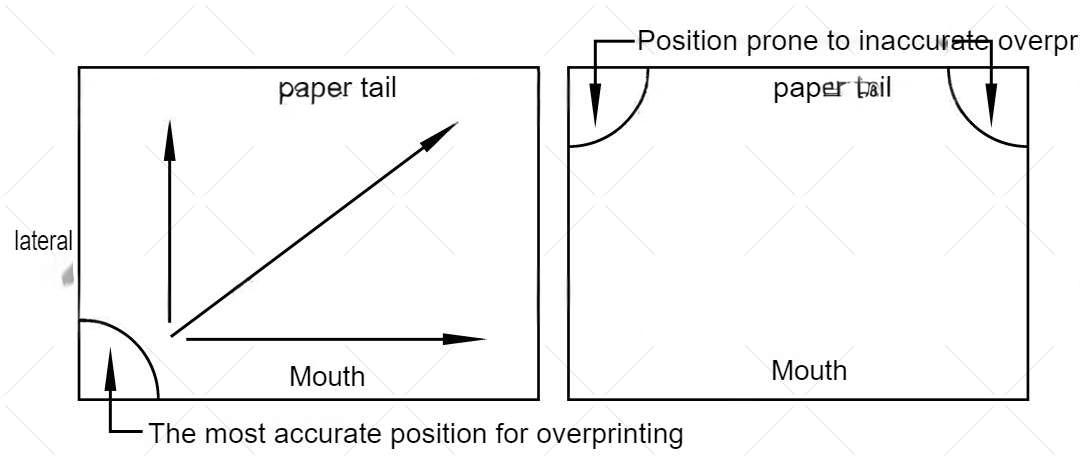

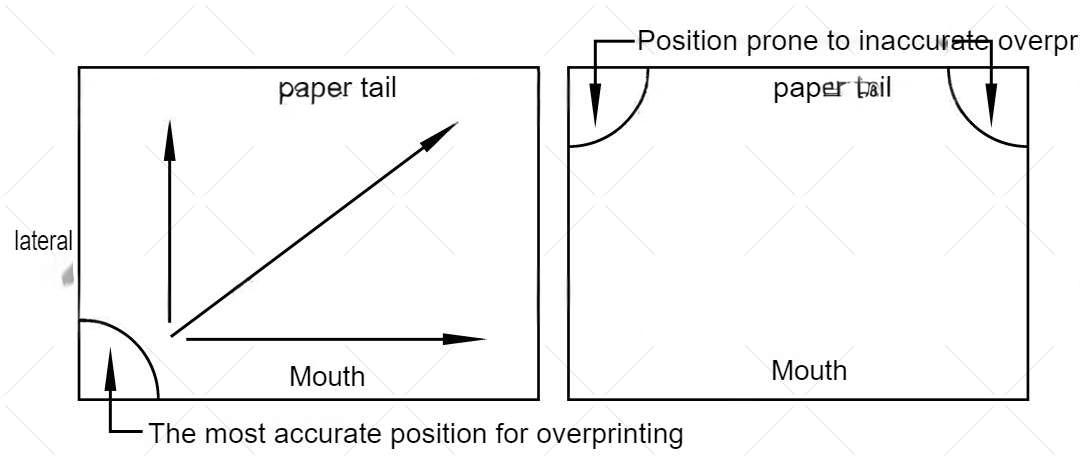

When printing, the substrate is gripped by the gripper.One end of the gripper is called the "gripper" and the other end is called the "tail" or "drag".Gripper teeth are used with greater force to send the paper, so in the paper, especially on the coating paper will leave obvious traces, the use of this trace, you can identify the direction of printing.Generally speaking, overprinting is not allowed to occur in most of the two corners of the end of the paper, such as Figure 1-3 right.

The positioning of the paper on the press is determined by the front stop gauge for the front-back direction position and the side stop gauge for the left-right direction position.

If there is misregistration in the left and right directions, the severe side is inevitably the part opposite the side stop gauge.

(1-3)Sheet overprint condition

When determining the accuracy of overprinting using the cross mark, it is important to specify the printing colour sequence.Otherwise, it will not be possible to analyse the reasons for inaccurate overprinting, or to draw the opposite conclusion.In the analysis of the so-called contraction or elongation of the substrate material, the size of the printing plate and the size of the substrate material in relative comparison, and all to the displacement between the cross mark to indicate the relative expansion and contraction.